Centrifugal Separator

Power Automatic Models

Product features

- Operation to the removal of the sludge is an automatic process. Manual operation is not required.

- It will be able to clean an amount of sludge with reverse direction drive of rotor and scraper.

PSF-100A

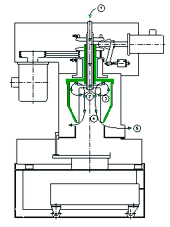

Structures

Processing cycle

- Process Liquid continiously flows up through the Feed Tube.

- The Impeller accelerated and distributes the Liquid into the Spinning Bowl.

- Liquid flows up The Pool Surface of the Bowl as the solids separate and compact at the Perimeter of the Bowl.

- The Clean Liquid passes around the Efficiency Ring and discharges through the Bowl Hub discharge ports and into the Frame Collection Chamber.

- The clarified liquid flows down the Drain Tubes and into the lower frame drain pan where it exists discharge fitting at the rear of the Centrifugal Separator.

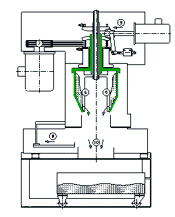

Automatic cleaning cycle

- Once the bowl fills capacity with waste solids,The Automatic cleaning Cycle is activated to remove the Solids. This Cycle is controlled by an adjustable Process Timer.

- When the cleaning cycle is activated, The Separator shuts off The Feed and brakes to a complete Stop.

- After the Free Liquid drains, The Sludge chute cover is pneumatically opened.

- A second Pneumatic Cylinder engages the plow mechanism’s clutch socket into the plow shaft. The sprocket then turns, counter rotating plow blades altermately, clockwise and counter clockwise.

- The Plowing Action discharges the compacted solids from the tapered Section of the Separator Bowl. The sludge drops through a chute into a waste receptacle below The Machine.

- Upon completion of the cleaning cycle, the sludge chute cover closes,the pneumatic cylinder retracts,The Process Timer resets,and the machine resumes its process cycle. A normal cleaning cycle takes less than 5 minutes.